Weighbridge Software That Transforms Industrial Weighing Operations

For industries handling high volumes of trucks, manual weighing systems are a hidden drain on time, accuracy, and profits. Errors in weight measurements, delayed ticketing, and lack of integration with ERP systems can cause operational bottlenecks, compliance issues, and financial losses.

Amity Weighbridge Software solves these challenges by offering a digital, automated, and cloud-based weighbridge solution that scales with your business. Whether you manage a logistics yard, mining facility, or manufacturing site, our software ensures accuracy, efficiency, and real-time visibility.

Weighbridge Software That Eliminates Errors and Speeds Up Operations

For companies handling hundreds of trucks daily, even small weighing errors can snowball into massive operational delays and financial losses. Amity Weighbridge Software is designed to tackle these challenges head-on—providing real-time weighbridge tracking, automated ticketing, and seamless ERP integration.

This isn’t just software; it’s a tool that transforms your weighing process into a fast, reliable, and auditable operation.

Stay Ahead with Value-Added Services

Key Features of Our Weighbridge Software

We deliver a smart, unmanned weighbridge software system that accesses data for all critical functions. It provides error-free weighing and eliminates the possibility of fraud and error. Our system is fully automatic and needs no workforce to monitor. You can also use our weighbridge software in remote locations as well.

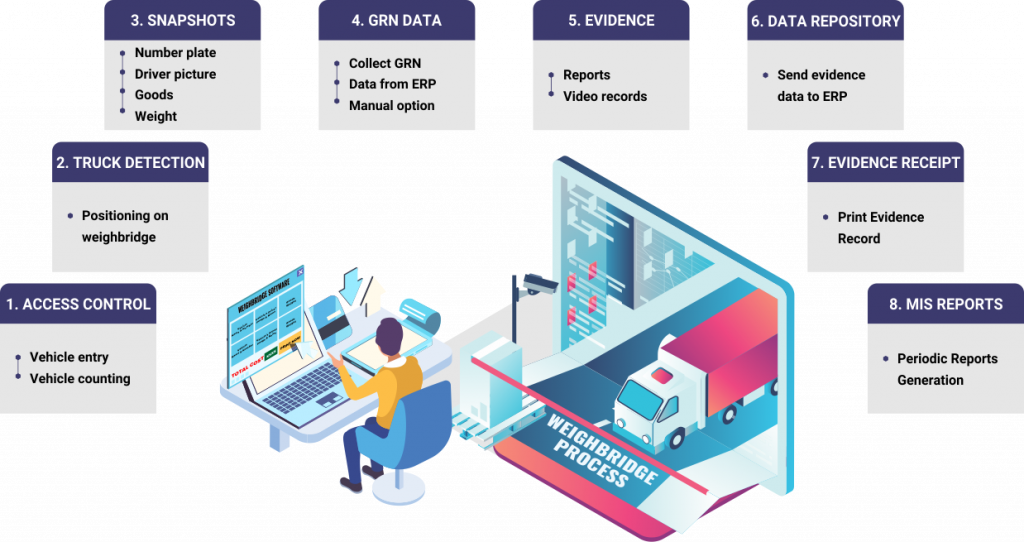

How Does Our Weighbridge Software Integration Work?

Key Benefits of Our Weighbridge Software

- It offers unmanned operation that eliminates the need of manual intervention and scope for errors.

- It makes the entire weighing process transparent and fair.

- The issuance of radio token eliminates the need for handling multiple printouts.

- It reduces workforce and improves yield, thereby offering a cost-optimized solution.

- Electronic transactions facilitate error-free data transmissions.

- It can be seamlessly integrated with ERP and other systems.

- It also notifies real-time information to customers via SMS and Email alters.

- Due to surveillance camera, chances of malpractices can be eliminated.

- It helps in easy monitoring of the weighment process and enhances overall business operations.

Why Choose Amity Weighbridge Software?

Unlike generic weighbridge software, Amity’s solution is designed for real operational environments:

-

Error-Free Operations: Eliminates manual mistakes

-

Faster Truck Processing: Reduces wait times

-

Regulatory Compliance: Automated reporting for audits

-

Scalable for Any Industry: Logistics, mining, manufacturing, and more

-

Cloud & ERP Integration: Real-time data wherever you are

Digital vs. Manual Weighbridge Systems

| Feature | Manual System | Our Software |

|---|---|---|

| Ticket Generation | Manual, error-prone | Automated, accurate |

| Queue Management | Slow, long lines | Real-time tracking, fast processing |

| ERP Integration | None | Seamless, automatic |

| Compliance Reporting | Manual, time-consuming | Instant reports with audit trail |

| Multi-Site Management | Difficult | Centralized dashboard |

Frequently Asked Questions

A: Digital solutions reduce errors, automate ticketing, integrate with ERP systems, and provide real-time tracking, unlike manual systems that rely on human input.

A: Yes. Centralized dashboards allow managers to monitor all weighbridges across multiple sites in real-time.

A: Absolutely. Our software is compatible with traditional digital and RFID weighbridges, ensuring faster and accurate operations.

A: Yes. Dashboards, alerts, and reports are fully accessible on web-enabled devices.

A: Yes. Weight data automatically syncs with accounting, inventory, and ERP systems, eliminating duplicate entry and reducing errors.